Added Value MDF

MELAMINE MDF

Melamine Medium Density Fibreboard is made from quality MDF panels overlaid with low-pressure melamine. It is engineered from fibres that are compacted together with resin, making it easy to cut, machine, and drill without splintering or chipping. With its pre-finished hard surface, Melamine MDF is easy to install and maintain. It is stain and scratch resistant.

Applications for Melamine MDF are endless for both vertical and horizontal surfaces as it can hold up under harsh wear conditions when applied in partition walls, shelves, and closets. Melamine MDF is used in residential, commercial, furniture and construction industries for numerous applications such as kitchen cupboards, built-ins, shelving cabinets, and many surfacing applications.

Melamine MDF Board OptionsWood-grain Designs

Beech

Oak

Cherry

Solid Colours

- Grey

- White

Doubled Sided Finish

- Pearl

- Satin

Single Sided Finish (other side as raw MDF)

- Matt

- Gloss

- Texture

For more options, please contact our sales team.

For more information on the above product, please visit our principal

Evergreen Group

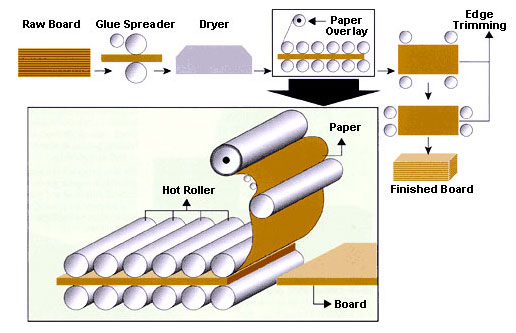

Paper Overlay MDF

Paper overlay uses PVAC glue to bond MDF with lightweight decorative paper that comes in variety of colours and wood grain patterns. It can also be coated with PU or Amino finishing. The applications for paper overlay MDF include knock down furniture (book cases & shelves), cabinet backing panels, drawer bottoms as well as door skins.

Logsearch also provide random grooved & regular grooved boards for wall panelling and partitions. The grooves are painted with black stains to highlight the panel effect.

Paper Overlay MDF Board Options

White

Black

Red

Blue

Grey

Beech

Cheery

Maple

Ash

Walnut

For more options, please contact our sales team.

Veneer MDF

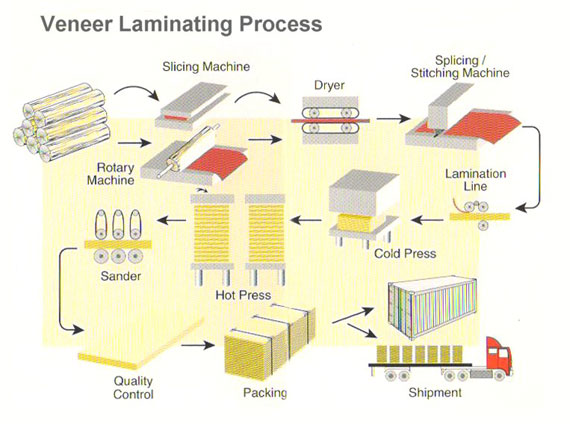

MDF has been largely been proven to have excellent processing qualities and countless applications. In today’s modern yet trendy society, veneered MDF has become the most exquisite and popular material for interior design as well as furniture production.

Flat, smooth, uniform, dense and free of knots, these are the characteristics of MDF surface, all of which make finishing operations easier and consistent. Only veneers from the best quality imported logs are carefully selected and laminated on the MDF. One of the distinguished features of MDF is that it can be laminated on one or both sides.

Veneer MDF Board Options

Red Oak

White Oak

Ash

Maple

Cherry

Beech

Pine

Teak

Note: Actual product may vary from images shown.

For more information on the above product, please visit our principal

Evergreen Group

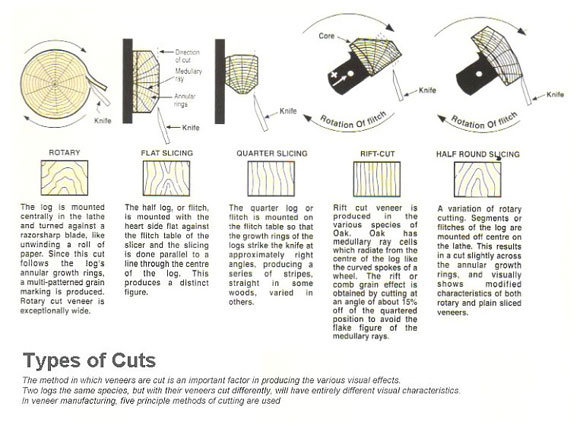

Types of cuts

The method in which veneers are cut is an important factor in producing the various visual effects. Two logs the same species, but with their veneers cut differently, will have an entirely different visual characteristics. In veneer manufacturing, five principle methods of cutting are used.

Did you know?

Particle board is a value for money product. Do you want to know more about Particle board?Read More

VALUE ADDED MDF THICKNESS AND SIZE:

Our Veneer MDF standard size is 1220mm x 2440mm with thickness ranges from 2.3mm to 30mm.

Our Melamine MDF standard size is 1220mm x 2440mm with thickness ranges from 6mm to 18mm.

We do not supply special size for value added MDF.